® to active risk management through the use of hail nets

Many car owners have experienced the consequences of a hailstorm at least once – instead of sparkling smooth sheet metal, their cars are covered with a multitude of large and small dents. After major events, such as in Munich in 2022, the media coverage is extensive – not only cars but also building facades, roofs, and windows are affected. Entire annual harvests in agriculture, for example, in the apple orchards by Lake Constance, can be threatened. And a significant hailstorm can lead to considerable damage on typical open automobile storage areas – where several thousand vehicles can be damaged simultaneously. As a long-standing player in the transport insurance industry for the German automotive sector, KA Köln.Assekuranz Agentur GmbH has repeatedly witnessed the consequences of such hail events and managed their regulation.

Figure 1: Hail dents on a vehicle (Source: KA)

In the past decade, the technology for repairing vehicles after a hailstorm has seen rapid advancements. Through standardized procedures, vehicles can now be restored more quickly and at significantly lower costs. In addition to numerous local repair companies, a handful of globally operating companies have established themselves as partners of automotive manufacturers and insurers.

These events do not appear completely by surprise. With the natural hazard analysis tool K.A.R.L., hail risk can be determined.

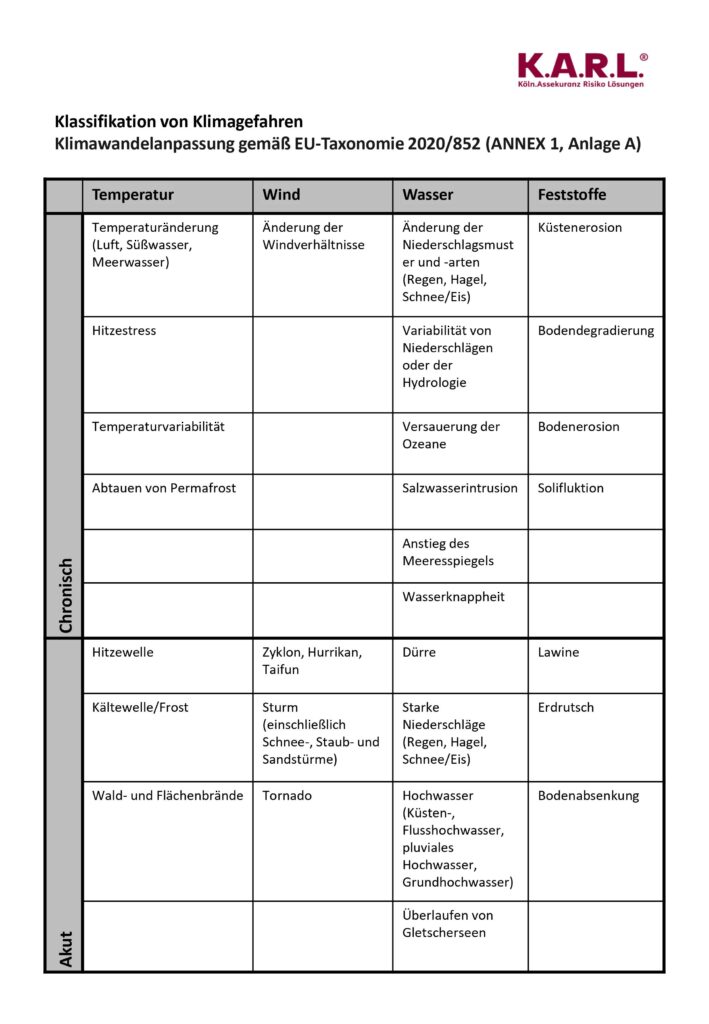

In 2008, K.A.R.L. made its debut with a model that could calculate the level of hail risk worldwide. This model fundamentally differed from all previous attempts to describe hail risk because it no longer relied on past damage data collected by the insurance industry. Instead, it examined the extent to which meteorological data and derived regional climate parameters (including annual and monthly temperatures, precipitation levels, and evaporation rates) influenced the occurrence of hail, either favoring or inhibiting it, or even compensating for each other. Since hail is often associated with thunderstorms, the frequency of lightning strikes was also incorporated into the model calculations.

Figure 2: Calculated global distribution of hail potentials, ranging from low (white) to very high (dark red) (Source: KA)

Figure 2 depicts the calculated global distribution of hail potentials, ranging from very low (white) to very high (dark red). The well-known hail risk hotspots – the Midwest and Eastern United States, areas in southern Brazil and neighboring states, South and Central Africa, the Mediterranean region, the southern slopes of the Himalayan Mountains, and the eastern coast of Australia – are clearly identifiable.

Since its introduction, the hail model has been regularly reviewed and adjusted as needed, incorporating the latest knowledge and experiences. For instance, the impacts of climate change have been considered by integrating model-calculated climate anomalies from the IPCC report into the level of hail risk. Like heavy rainfall, the hail hazards calculated by K.A.R.L. are dynamically adjusted annually to reflect the conditions of climate change. The expected changes due to rising temperatures do not always result in an increase in hail risk. In some currently highly vulnerable areas of the world, hail risk may even decrease slightly.

But why not prevent damages altogether?

Beyond a certain probability of hail and exposure of an open storage area, investing in hail protection becomes worthwhile.

In the course of their review and inspection of several hundred storage facilities worldwide, the risk managers at KA Köln.Assekuranz have encountered a variety of different solutions. From a risk management perspective, the practice of “hail shooting” with cannons or “cloud seeding” with planes is pointless and serve the purpose of reassuring rather than having any actual measurable effect. Protective mats that must be applied individually to each vehicle are not convincing in terms of handling on an industrial scale. Not to mention the damage to the paint underneath these mats if dust and sand had settled on them beforehand. The focus is primarily on sheltering by hail nets.

However, as there was often little objective information available about the quality of these solutions, KA Köln.Assekuranz Agency GmbH initiated several projects to approach the issue comprehensively. One of these projects included a competition in 2019 with students from the Transport and Logistics program at the Hochschule Bremerhaven (Bremerhaven University of Applied Sciences).

Figure 3: TÜV hail impact testing facility (Source: TÜV/KA)

To our relief, the practical test did not yield any outright failures. For the test, selected hail net samples were tested under continuous bombardment in collaboration with TÜV Rheinland, and the limits of their resistance were assessed using a hail cannon. However, typical weaknesses were identified in several providers. Frequently, these weaknesses were related to the fastenings and suspensions, which can be subjected to significant stress upon the impact of large hailstones. Special attention should be directed towards these aspects, as well as tension, when developing local protection concepts. Manufacturers of such systems have varied approaches to the discharge of hail nets. The most efficient systems are those that allow for controlled relief, as otherwise, unintended stresses can quickly occur at the drainage areas, or unnecessarily high and costly material thicknesses must be employed.

“The examination of hail nets alone is not enough; it depends on an entirely consistent system. The weak points are often the fastenings and suspensions”, explains Dipl. Ing. Jürgen Sommer from TÜV Rheinland. Additionally, local climate conditions must be taken into account – how long does the hail season last? What stresses from storms, UV radiation, or frosty and snowy winters need to be considered when selecting the system and anchoring? Due to the significant investment involved, the lifespan of an effective hail pr tection system should be maximized and not reduced to just a frame with ineffective threads, as was recently found at a storage facility in Southern Europe.

Together with its clients, many of whom are from the automotive sector, KA Köln.Assekuranz can prepare financially sound decisions using concrete K.A.R.L.® analyses and its well-founded insurance expertise to assist in the conceptualization and selection of hail protection measures. Ultimately, customers want to receive a brand-new vehicle on time. For an automobile manufacturer, many damaged vehicles can lead to numerous logistical disruptions and costs. Matthias Müller, Head of K.A.R.L.-Team and Sebastian Kempka, Consultant in the Nautical/Technical Risk Services are the contacts at KA Köln.Assekuranz: „With a K.A.R.L. site analysis, we assess the hail risk at our customers‘ locations and significantly reduce this vulnerability with a tailor-made protection concept.“

If you would like to discuss this paper with us, we look forward to hearing from you.